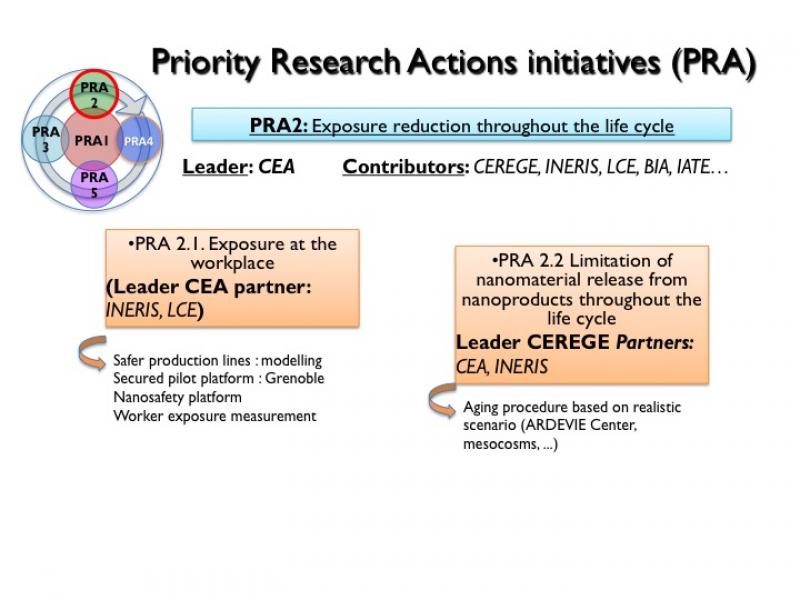

PRA 2 - Exposure reduction throughout the life cycle

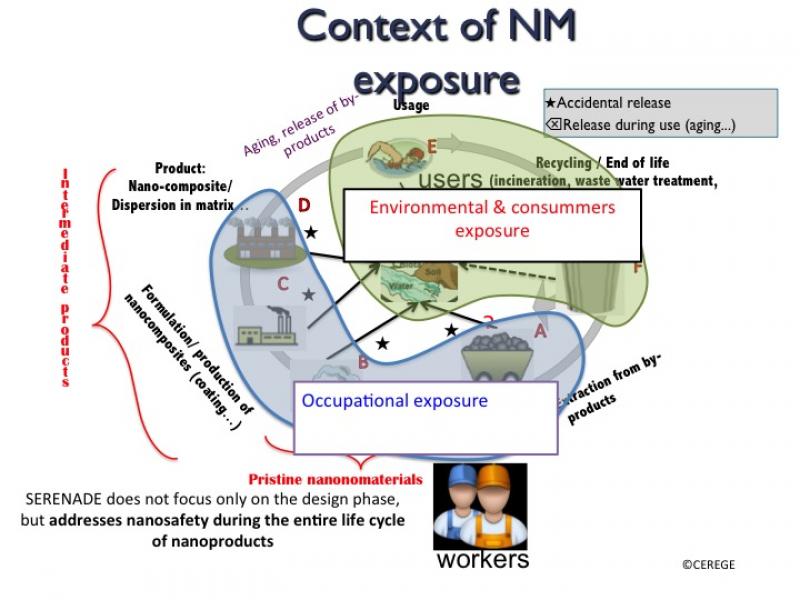

The objective is to reduce the exposure to nanoparticles, nanomaterials and nano by-products during the whole life cycle of nanomaterials from synthesis (occupational exposure), use of nano (release of nano by-products under conditions of normal use and/or accidents), end of life.

Exposure at the workplace

Safer production lines: A special focus is devoted to the understanding of the adhesion forces to surfaces and fibers, in order to design efficient procedure(s) for nanoparticle clean-up from workplace/lab surfaces (benchtops, walls, etc.) and protection suits. To enable this task, the aggregation kinetics of the nanoparticles in dilute and denser regimes will be investigated through experimentation and mechanistic modeling.

A secured pilot platform has been implemented in the Grenoble Nanosafety platform.

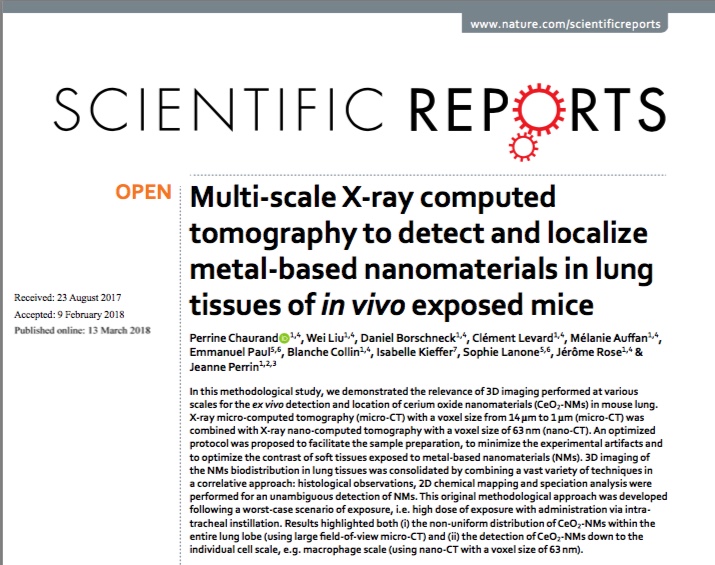

Worker exposure measurement: It is necessary to develop new nano-specific methods of personnel sampling and the associated measurement techniques to quantify the actual doses, i.e. exposure/non-exposure of the workers.

Contact : Delphine Boutry, LITEN

Limitation of nanomaterial release from nanoproducts throughout the life cycle

Protocols developed in this task based on realistic exposure scenarios. The first step towards robust protocols in then to define these exposure scenarios as function of product category and anticipated use.

Among the products on which this project will focus, cement, paints and stains may be treated in a broad construction context. Parameters to consider in the exposure scenario for outdoor applications include illumination cycles (UV), rainfall, temperature variations (amplitude, periodicity), leaching in abiotic and biotic media (e.g. bridge piles)...

For plastic composites, mechanical stresses will be relevant factors for some applications; for example parameters such as abrasion, scratches or shocks will be considered to simulate the use of car bumpers.

For nano-enabled food packaging, the challenge here will be to define meaningful exposure protocols without having to consider one by one the various food items in contact with the packaging.

To implement the exposure scenarios, we will use the infrastructures present in the network:

- the ARDEVIE Center (CEREGE and INERIS at Aix-en-Provence) fully equipped climate chamber, a modified Soxhlet...,

- the iCEINT aquatic mesocosms.

Contact : Mélanie Auffan, CEREGE